Aures is a company based in southern Poland, in the vicinity of a large industrial centre.

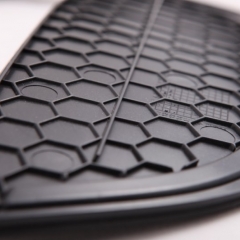

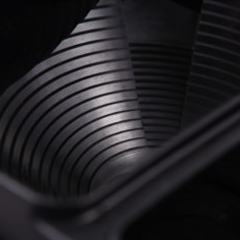

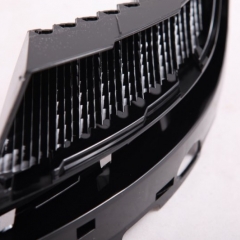

With over 20 years of experience working with the best car manufacturers in Poland, we come as the leader among manufacturers of plastic components for the automotive industry.

We specialize in manufacturing high-tech components with the injection moulding method.

We presently have a staff of 170 people working in the plant covering an area of 24,000 m2, including 7,000 m2 of production halls and storehouses. The company is located at a site owned by itself.

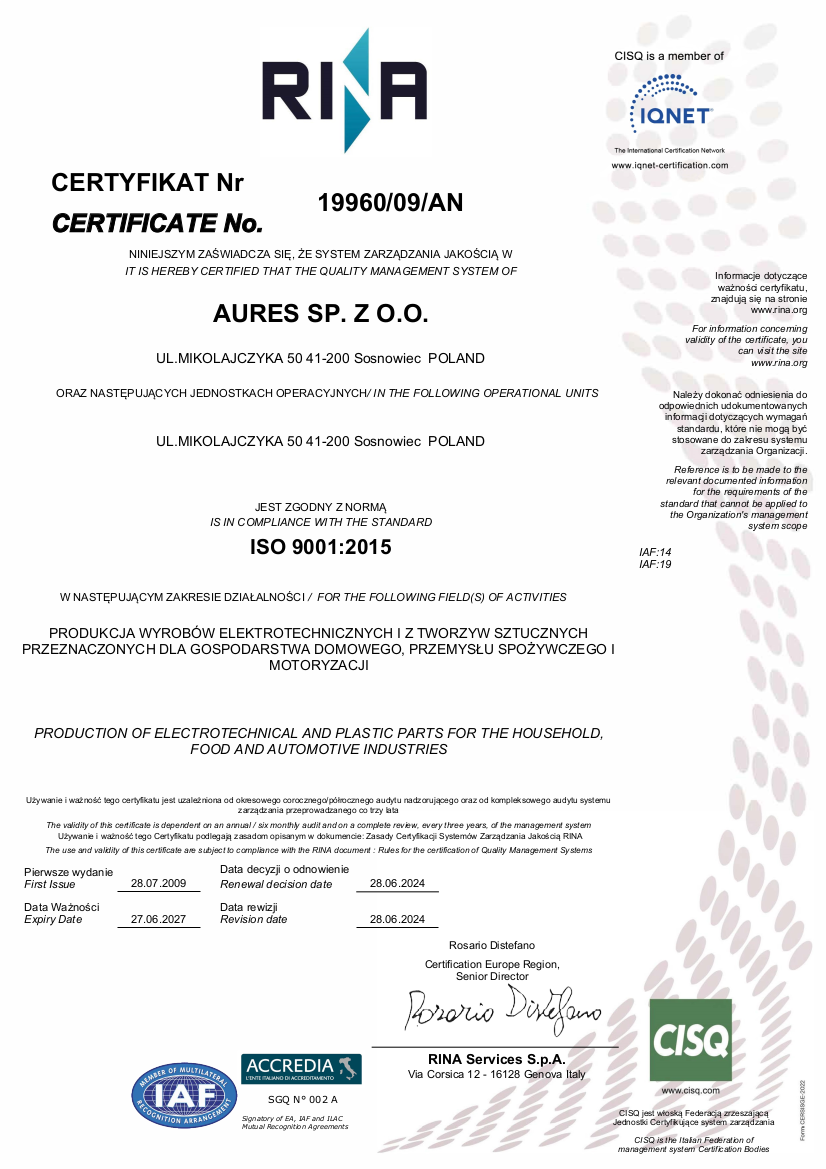

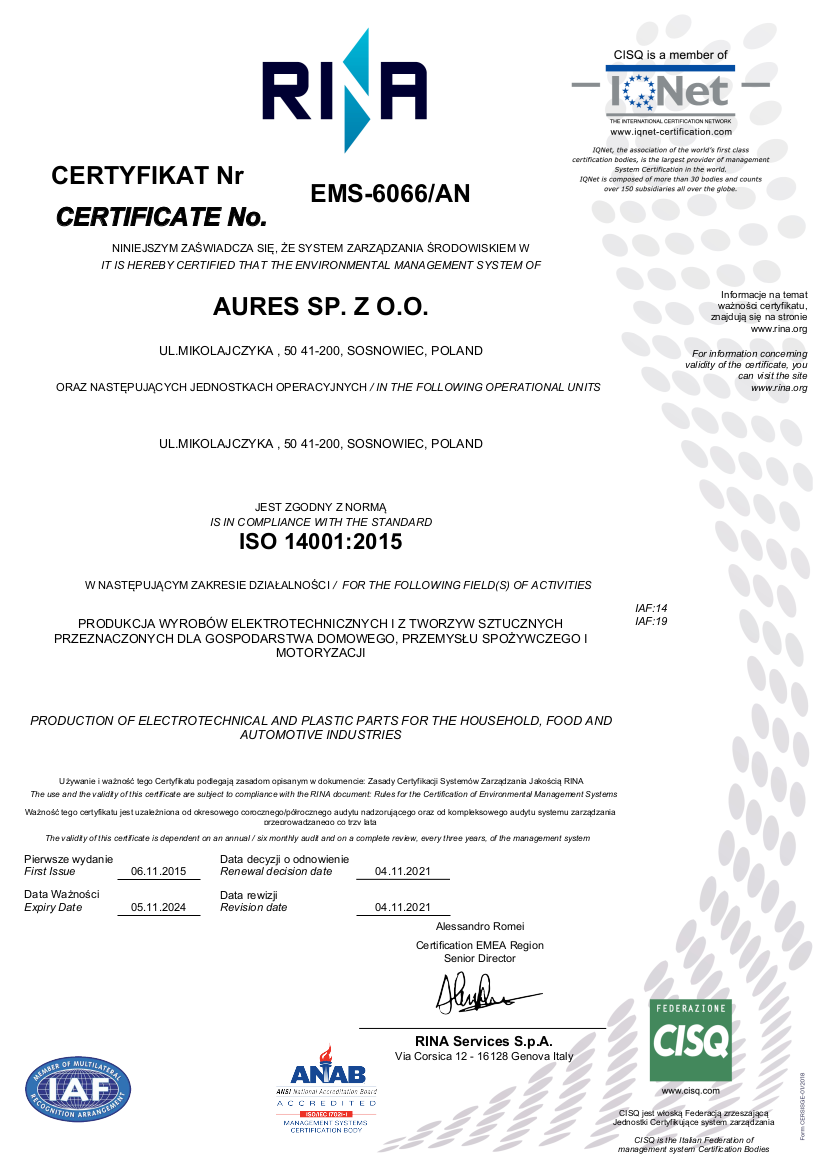

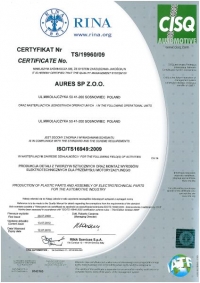

Our advantage is a well-trained team of experts constantly improving their competences and the highest standards we comply with, both in terms of environmental protection and the quality system management, as evidenced by certificates ISO – ISO 9001, ISO TS 16949 and ISO 14001.

The company has been also positively audited under the World Class Manufacturing scheme, which means it complies with the highest standards of functional and economic management, which is geared towards maximum reduction of losses and waste, improvement of efficiency and safety of manufacturing processes.

We are an ever growing company committed not only to raising its staff’s competences but also investing in new technologies, which helps our products meet all high standards of the automotive industry. And most importantly, we are one of the most progressive companies in the south of Poland.

COMPANY’S VISION

We seek to achieve the leading position on the world plastics processing market by improving all processes related to quality, safety, reduction of costs and environmental protection.

COMPANY’S MISSION

Aures recognizes customers’ satisfaction as the ultimate value resting on the highest quality of the company’s reasonably priced products. Our products must fully satisfy our customer’s needs and expectations. To that end, we have developed:

INTEGRATED MANAGEMENT SYSTEM, which:

Requires us:

- To be fully professional at all times – We apply quality-related work techniques and methods and take account of all issues related to environmental protection and prevention of pollution as well as health and safety precautions during daily tasks. All of this to make sure that company’s processes are developed in a reliable and effective way;

- To improve our education – Our staff’s outstanding skills guarantee that all quality, environmental protection, legal and HSW requirements are complied with;

- To make improvements – We believe in a ‘no defects strategy’, whereby we do management on the basis of clearly specified targets;

- To keep up the World Class Manufacturing level, both in terms of manufacturing and individual employees' levels;

Gives us:

- Satisfaction with work – Everybody cares for their workplaces and uses materials in an efficient way;

- Conditions for active work that enable elimination of risks and prevent accidents, occupational diseases and near-miss incidents.